Robotunits is a global manufacturer of a Modular Automation System for production equipment. This includes Conveyor and Linear Motion Technology, Material Handling, as well as Machine Framing and Guarding. The core of Robotunits is its unique aluminum extrusion & fastening technology which strictly follows a lean manufacturing concept of "More with Less".

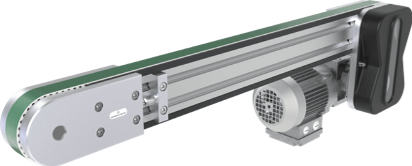

Configure your belt conveyors according to your requirements: your choice of belt types, customized drive options, position, and speed. Each Belt Conveyor can be delivered with a conveyor stand, flexible side guides and many other accessories from the Modular Automation System.

The Powered Roller Conveyors are 24V conveyors for precise and efficient transportation of containers, totes or boxes. Ideal for zero-pressure accumulation, each zone can be controlled separately. The control units are pre-installed inside the extrusion, covered and ready to use (plug-and-play).

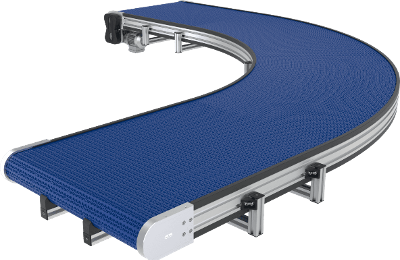

The Modular Belt Conveyor is designed for tough applications, accumulation, transporting parts with sharp edges or heavy loads. Straight, curved, and inclined sections can be combined with just a single drive. This design allows products to be pushed off laterally. A wide range of belt options and accessories are also available.

The Timing Belt Conveyors are used for the precise positioning and transportation of bulky or heavy parts. A v-guided timing belt guarantees precise tracking. The belt surface is available with different covers or attachments. High-quality connection shafts allow you to utilize multi-lane setups.

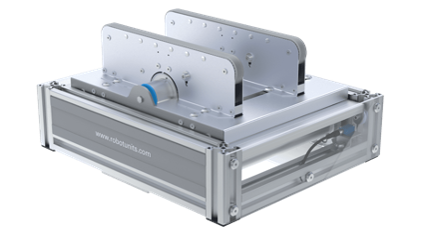

The safe and compact transfer unit with an angle of 90° in both directions is designed to be particularly space-saving and can be subsequently installed in existing lines. As with all Robotunits roller conveyor units, the electronic controls are fully pre-installed and they are compatible with the complete modular system.

The stepless rotation range with fully integrated electronic controls can be configured from 0° to 270° and guarantees the individual and correct distribution of conveyed goods in production. Depending on individual requirements, the turntable can alternatively be equipped with a belt conveyor, timing belt conveyor or modular conveyor.

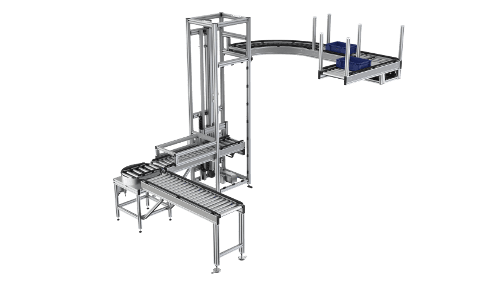

The variable Robotunits Lift Station enables the energy-efficient transport of products on two levels within industry and production areas. With a speed of up to 1 m/s and an acceleration of up to 3 m/s², goods are transported within dimensionally stable containers to the right place. The standard conveying height is up to 5 meters. The Highlight: The complete conveyor technology from the Robotunits Modular Automation System can be integrated. For roller conveyor systems the Lift Station is available as a Plug and Play solution. This makes conveying on two levels child’s play.

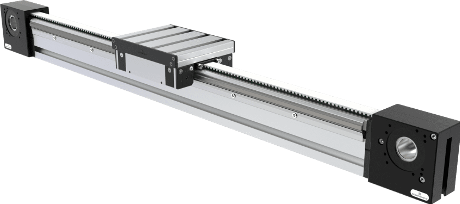

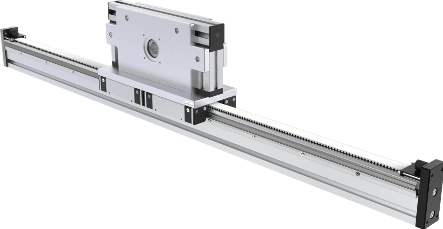

The Robotunits Linear Motion System is based on their proven Extrusion and Fastening Technology. Its robust and modular construction saves time in design and assembly. Single or double carriages are available and the system allows for the direct attachment of an energy chain.

Used as individual unit or x-y-z gantry for the transport and exact positioning of parts.

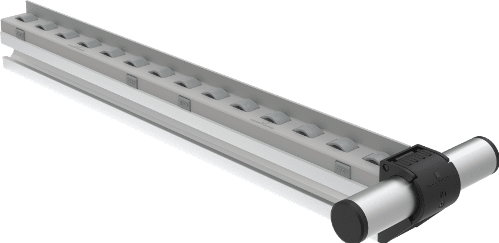

The Robotunits Material Handling System, (MBS PickStar Rolling), combines the unique Extrusion and Fastening Technology with individually configurable roller tracks. The system is designed to transport boxes, totes or cartons up to 30 kg. Track widths and lengths are freely adjustable.

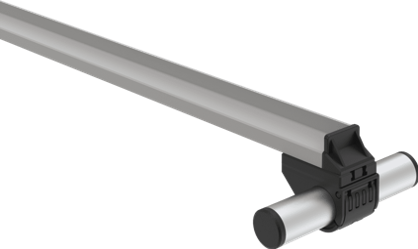

The Robotunits Material Handling System, (MBS PickStar Sliding), can be used in combination with the aluminum Round Tube or the Extrusion Technology. This makes the system particularly flexible and easy to design.

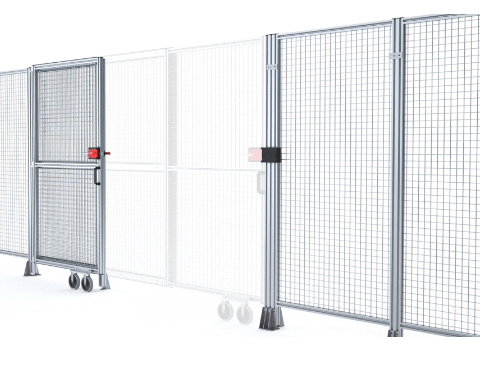

The Robotunits Safety Fence Basic System is ideal to safeguard numerous applications in machine building and production automation. It provides strong impact safety and can easily be installed by one person.

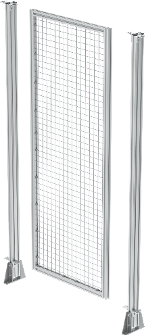

In the Robotunits Safety Fence Allround System, each panel can easily be installed between pre-installed fence posts by one person. For large area accessibility, e.g. equipment replacement or modifications, panels can be quickly removed and re-installed.

Whether for maintenance, repairs, or work on the machine: the Robotunits telescopic sliding door gives you optimal access to your machine. The simple, fast and space-saving handling helps with entering and leaving the machine area in the shortest possible time – whether by foot or with your forklift. Free passage of up to 4 meters can be achieved as standard, for special solutions we are available for consultation.

Do you need help in choosing the right safety fence elements? Whether sliding door, door element, basic element a combination of all, we will find the right safety fence design for you.

With the Cobot Station, machine operation, assembly, adhesive applications or simple pick & place tasks can be quickly tackled. Application-specific components such as tool holders, sensors or probes can be easily attached to the profile slots. Thanks to storage space for the control elements and locking castor wheels, the base ensures maximum mobility for individual application options.

![]() Download Cobot Station Datasheet

Download Cobot Station Datasheet

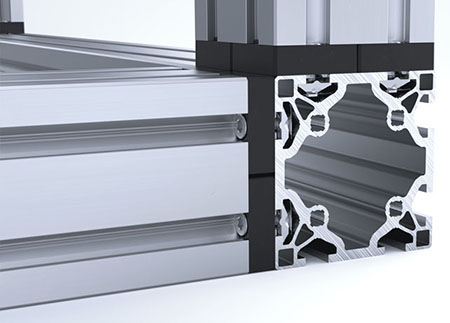

One system for everything: the core of the Modular Automation System is the unique fastening technology for aluminum extrusions. Two extrusion sizes that can be combined with each other in 40mm and 50mm series, as well as a matching standard T-slot size of 14mm that is uniform in all extrusions, open up a wide range of possibilities.

Robotunits’ unique fastening technology of aluminum extrusions includes two extrusion sizes that can be combined with each other, as well as a matching standard T-slot size of 14mm that is uniform in all extrusions, opening up a wide range of possibilities.

Elevate your next project with sleek, durable, and stylish 40mm and 50mm black anodized aluminum extrusion, perfect for a variety of applications.

Robotunit's black anodized T-slot aluminum extrusions offer both durability and aesthetic appeal. The anodized black finish provides enhanced corrosion resistance and wear resistance, ensuring longevity in harsh environments.

These extrusions feature T-slots for easy assembly and customization, allowing for the creation of sleek and modern structures, whether used for framing, machinery, or architectural elements.

R.R.Floody Company is a Robotunits distributor in Chicago and Northern Illinois. We offer technical support to help our customers solve their applications.