ROEQ produces specialized equipment for MiR (Mobile Industrial Robots). Their flexible logistics solutions are aimed to move you closer to a hands-free operation at your factory or facility.

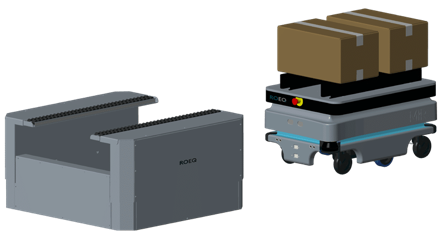

TR600 & TR1150 are heavy duty top rollers for your MiR600 and MiR1350 mobile robots. They can pick up and deliver heavy goods between conveyor stations on your production line and are ideal for transporting US and euro pallets.

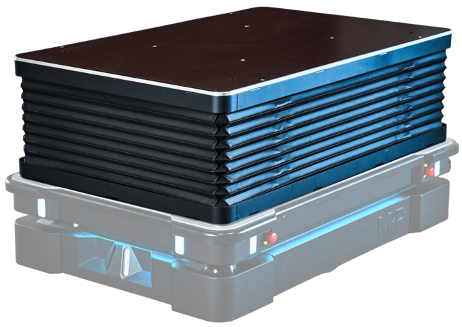

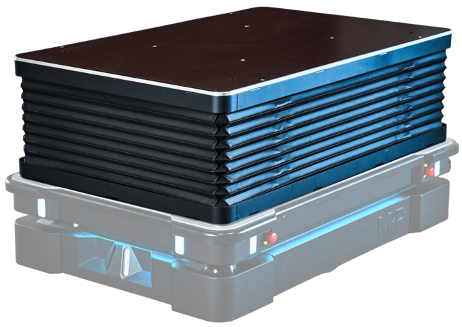

The ROEQ TR1000 Auto enables your MiR600 or MiR1350 AMR to transfer heavy goods between conveyor stations at different heights. The automatic height adjustments, with a large stroke – 240 mm/9.4” –gives the flexibility to adjust to your existing setup.

TR125 Manual 250 is a top roller for the MiR250. Height of top roller can be set manually.

TR125 Auto 250 is a top roller for the MiR250. A scissor mechanism is built in that allows automatic adjustment of heights. Height of each pick-up/delivery point is set up in the GUI. It can pick up and deliver at different heights.

The ROEQ TMC3000 is made as a base, and can be used with a standard rack attached or as a base for a customized application. A MiR100™/MiR200™ will align the RB100 Rack Base with its destination, which secures precision and stability in any work environment.

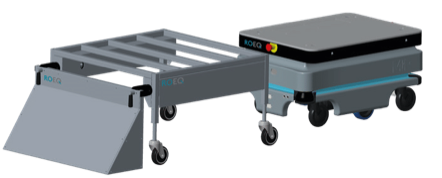

The basic functionality of the TMS-C300Ext system is to perform automated internal pallet transport with the MiR250. The TMS-C300Ext is specially designed for easy access to the emergency stop when handling pallets, skids, boxes etc. – with lengths up to 1.2m.

The TMR150 is made as a base and can be used with a standard rack attached or as a base for a customized application. A MiR100/MiR200/MiR250 with AM250 will align the Rack150 base with its destination, which secures precision and stability in any work environment.

The basic functionality of the TMS-C300Ext system is to perform automated internal pallet transport with the MiR250. The TMS-C300Ext is specially designed for easy access to the emergency stop when handling pallets, skids, boxes etc. – with lengths up to 1.2m. The ROEQ S-Cart300 can be used with our TMS-C300Ext top module and adds flexibility to your facility.

When combined with the ROEQ S-Cart1500W, this top module can transport up to 800kg with the MiR500 and MiR600 and up to 1500kg with the MiR1000 and MiR1350.

The ROEQ TMS-C500 Ext is a top module designed to be used with the ROEQ S-Cart500 series on the MiR250. This extended top module enables the MiR250 to safely handle long loads, and when combined with the S-Cart500 series can pick up, transport and drop off payloads of up to 500kg, effectively doubling the payload potential of the robot. Developed for easy maneuverability of high payloads – ideal for space constrained areas.

The basic functionality is to use MiR100™/MiR200™ with the Lifter Top Module to move goods between logistic points. The Lifter Top Module can be customized to support a variety of pallets and fixtures that are already a part of an existing assembly flow.

TML1000 is for the MiR500 or MiR1000. It lets you pick up and deliver goods from your lines at different heights. Lifter doesn’t have to return to its lowest position for transport to reduce operation time. It’s compact when lowered (140 mm/5.5”). It works with pallet racks, stationary pick-up stations with rollers/gravity rollers, and is equipped with mounting holes for customized accessories (e.g. fork plates) .

TML1000 is for the MiR500 or MiR1000. It lets you pick up and deliver goods from your lines at different heights. Lifter doesn’t have to return to its lowest position for transport to reduce operation time. It’s compact when lowered (140 mm/5.5”). It works with pallet racks, stationary pick-up stations with rollers/gravity rollers, and is equipped with mounting holes for customized accessories (e.g. fork plates).

The new ROEQ Top Module Lifter TML200 for the MiR250 is a flexible top module that can lift, transport and drop off pallets, crates and racks, as well as shelf carts. A versatile solution for transporting different types of loads with only small adjustments.

The basic functionality is to use MiR100™/MiR200™ with the Lifter Top Module to move goods between logistic points. The Lifter Top Module can be customized to support a variety of pallets and fixtures that are already a part of an existing assembly flow.

The ROEQ Cart300P can be used as a permanently attached cart on a MiR robot. This application adds stability and enables increased payload. Furthermore, the system can utilize the docking facility if needed. The type of application can vary from a robot arm to a base for a conveyor belt – and a lot of applications in between.

The ROEQ TMC3000 is made as a base, and can be used with a standard rack attached or as a base for a customized application. A MiR100™/MiR200™ will align the RB100 Rack Base with its destination, which secures precision and stability in any work environment.

The ROEQ S-Cart1500W is a heavy-duty cart that can take loads of up to 1500kg/ 3307lbs. It is designed to work with the ROEQ TMS-C1500 top module on the large MiR robots (MiR1000 and MiR1350). Note: it can also work with the MiR500 and MiR600 with a payload of 800kg/1764lbs.

Robot compatibility: MiR250, MiR Shelf Carrier 250 TM

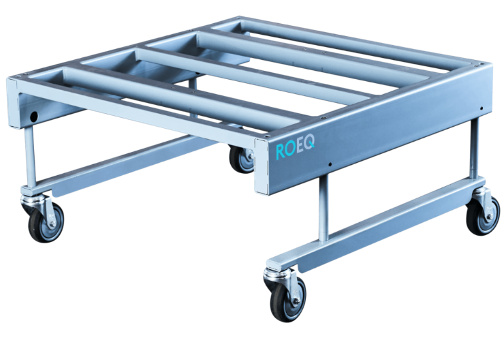

Works without docking stations. Pick-up and drop-off in free space. Attachment holes in the corners for attaching customized equipment.

Robot compatibility: MiR250, MiR Shelf Carrier 250 TM

Extra wheels for added manual maneuverability. Works without docking stations. Pick up and drop off in free space. Attachment holes in the corners for attaching customized equipment.

The S-Cart300L for the MiR250 has been developed to work with the TML200 top module. It enables the TML200 to lift and transport payloads up to 170kg/374lbs. on the MiR250 – ideal in situations where floors have reduced traction, such as polished or dusty floors. The cart attaches to the TML200 using the centering cones which are mounted on the TML200 top module.

Robot compatibility: MiR250, MiR Shelf Carrier 250 TM

Increased wheelbase -> increased tilt stability. Designed for transport of longer goods. Extra wheels for manual maneuverability. Works without docking stations. Pick up and drop off in free space. Attachment holes in the corners for attaching customized equipment.

Robot compatibility: MiR250

A shelf cart developed to pick up, transport and drop off loads of up to 500 kg/1100 lbs, in free space, when combined with the ROEQ TMS-C500 Ext top module and the MiR250.

Robot compatibility: MiR250

A shelf cart developed to pick up, transport and drop off loads of up to 500 kg/1100 lbs, in free space, when combined with the ROEQ TMS-C500 Ext top module and the MiR250. The increased wheelbase gives increased tilt stability for longer goods.

The basic functionality of the AM250 system is to allow the MiR250 to work in the same fleet as the MiR100/200. Flexibility is added to your facility by the opportunity to use three of ROEQs existing top modules on both your MiR100/200 and MiR250 in the same fleet.

GuardCom will revolutionize the way your MiR AMRs transfer goods between stationary conveyor stations. Instead of relying on wifi connections which can be unstable, GuardCom connects directly to your ROEQ top roller and to the stationary conveyor station, eliminating the need for receiving stations that take up valuable floor space. It uses well-proven sensor technology to do the handoff between the robot and the conveyor, checking that the robot is in place and ready in order to ensure the safety of the goods to be transported.

R.R.Floody Company is a ROEQ distributor in Chicago and Northern Illinois. We offer technical support to help our customers solve their applications.